Position:Jayuseal > Ring Gasket > IX Seal Ring Gaskets

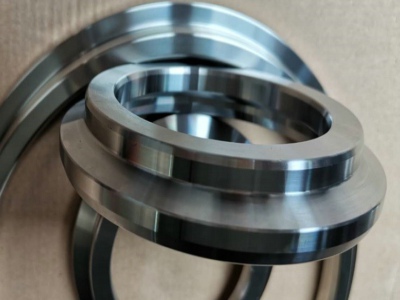

IX Seal Ring Gaskets

Posted Time: 2022-09-05 08:23:40Author: Ring GasketSource: JayusealView:

IX seal ring gasket product information

IX seal ring gaskets are solid metallic profiled gaskets and often supplied with corrosion resistant coating.IX seal ring gasket materials

IX seal ring gasket material is usually chosen to be compatible with the flange material, i.e. SS316 seal ring gasket in SS316 compact flange.For in service use, Table 1 gives a guideline for seal ring selection.

Table 1 – IX seal ring gasket materials selection

| Flange material | Service temperature | ring material | ring PTFE colour |

| Carbon steel | -50°C to +250°C |

Carbon steel CS360LT or low alloy steels, e.g. AISI 4140 |

Blue |

| Stainless steel | -50°C to +250°C | 22Cr Duplex | Yellow |

| Stainless steel | -50°C to +250°C | 17/4-PH | Orange |

| Stainless steel | -101°C to +250°C |

Nickel alloys such as Alloy 625, Incoloy 800, 825 ,or similar |

Black |

The thickness of PTFT coating shall be 10 µm to 30 μm. The coating colour of IX ring gaskets shall be in accordance with the requirements of Table 1.

Silver coating available to meet customer's need

Metallic IX seal ring gaskets shall have dimensions and tolerances as specified in Table 2. Medium tolerances to ISO 2768-1 shall be used for non specified tolerances.

IX seal ring gaskets specifications

Table 2 – Dimensions of IX seal ring gaskets and their weights

| NPS | IX size |

DG1 mm |

DG2 mm |

DG3 mm |

DG4 mm |

DG5 mm |

DG6 mm |

DG7 mm |

DG8 mm |

HG1 mm |

HG2 mm |

HG3 mm |

HG4 mm |

HG5 mm |

RG1 mm |

Weight kg |

| ½ | IX15 | 22.2 | 27.91 | 28.46 | 28.66 | 27.42 | 29.14 | 30.19 | 24.7 | 0.35 | 1.2 | 3.3 | 3.8 | 10 | 0.5 | 0.02 |

| ¾ | IX20 | 27.2 | 32.93 | 33.47 | 33.67 | 32.43 | 34.16 | 35.2 | 29.7 | 0.35 | 1.2 | 3.3 | 3.8 | 10 | 0.5 | 0.03 |

| 1 | IX25 | 34.2 | 39.95 | 40.49 | 40.69 | 39.45 | 41.18 | 42.22 | 36.7 | 0.35 | 1.2 | 3.3 | 3.8 | 10 | 0.5 | 0.03 |

| 1½ | IX40 | 49.3 | 55.84 | 56.38 | 56.58 | 55.29 | 57.11 | 58.21 | 51.9 | 0.35 | 1.27 | 3.48 | 4 | 10.56 | 0.5 | 0.05 |

| 2 | IX50 | 61.3 | 68.43 | 69.08 | 69.32 | 67.87 | 69.89 | 71.13 | 64.4 | 0.42 | 1.41 | 3.89 | 4.5 | 11.78 | 0.6 | 0.08 |

| 2½ | IX65 | 74.4 | 82.14 | 82.79 | 83.03 | 81.47 | 83.69 | 85.05 | 77.8 | 0.42 | 1.56 | 4.28 | 4.9 | 12.98 | 0.6 | 0.12 |

| 3 | IX80 | 89.5 | 97.74 | 98.49 | 98.77 | 97.04 | 99.47 | 100.96 | 93.3 | 0.49 | 1.71 | 4.7 | 5.4 | 14.24 | 0.7 | 0.17 |

| 4 | IX100 | 115.7 | 125.17 | 126.04 | 126.36 | 124.39 | 127.15 | 128.85 | 120.1 | 0.56 | 1.94 | 5.34 | 6.2 | 16.19 | 0.8 | 0.28 |

| 5 | IX125 | 142 | 152.66 | 153.64 | 154 | 151.82 | 154.87 | 156.75 | 146.7 | 0.63 | 2.15 | 5.92 | 6.8 | 17.94 | 0.9 | 0.42 |

| 6 | IX150 | 170.2 | 182.17 | 183.25 | 183.66 | 181.27 | 184.61 | 186.66 | 175.4 | 0.7 | 2.36 | 6.48 | 7.5 | 19.64 | 1 | 0.62 |

| 8 | IX200 | 220.5 | 233.46 | 234.66 | 235.1 | 232.35 | 236.19 | 238.54 | 226.5 | 0.77 | 2.68 | 7.38 | 8.5 | 22.36 | 1.1 | 0.99 |

| 10 | IX250 | 274.9 | 292.64 | 294.05 | 294.57 | 291.47 | 295.78 | 298.42 | 281.7 | 0.91 | 3.02 | 8.31 | 9.6 | 25.2 | 1.3 | 1.85 |

| 12 | IX300 | 325 | 341.13 | 342.65 | 343.21 | 339.87 | 344.52 | 347.36 | 332.5 | 0.98 | 3.26 | 8.96 | 10.4 | 27.15 | 1.4 | 2.18 |

| 14 | IX350 | 357.1 | 373.87 | 375.38 | 375.94 | 372.48 | 377.34 | 380.32 | 365 | 0.98 | 3.42 | 9.39 | 11 | 28.46 | 1.4 | 2.6 |

| 16 | IX400 | 409.3 | 427.36 | 428.98 | 429.58 | 425.83 | 431.08 | 434.27 | 417.9 | 1.05 | 3.66 | 10.05 | 11.9 | 30.47 | 1.5 | 3.43 |

| 18 | IX450 | 459.4 | 478.9 | 480.63 | 481.27 | 477.3 | 482.85 | 486.23 | 468.6 | 1.12 | 3.87 | 10.65 | 12.7 | 32.28 | 1.6 | 4.38 |

| 20 | IX500 | 511.6 | 531.45 | 533.29 | 533.97 | 529.78 | 535.63 | 539.2 | 521.4 | 1.19 | 4.09 | 11.24 | 13.5 | 34.06 | 1.7 | 5.27 |

| 22 | IX550 | 561.7 | 583.04 | 584.99 | 585.71 | 581.47 | 587.44 | 591.18 | 572.1 | 1.26 | 4.28 | 11.78 | 14.3 | 35.69 | 1.8 | 6.48 |

| 24 | IX600 | 611.9 | 633.64 | 635.7 | 636.46 | 632.2 | 638.26 | 642.16 | 622.8 | 1.33 | 4.47 | 12.29 | 15 | 37.25 | 1.9 | 7.55 |

| 26 | IX650 | 664 | 686.37 | 688.42 | 689.18 | 684.99 | 691.09 | 695.16 | 675.5 | 1.33 | 4.66 | 12.81 | 15.7 | 38.81 | 1.9 | 8.74 |

| 28 | IX700 | 714.1 | 738.01 | 740.17 | 740.97 | 736.81 | 742.94 | 747.16 | 726.1 | 1.4 | 4.83 | 13.28 | 16.3 | 40.25 | 2 | 10.4 |

| 30 | IX750 | 766.3 | 790.65 | 792.92 | 793.77 | 789.58 | 795.79 | 800.16 | 778.8 | 1.47 | 5 | 13.76 | 17 | 41.69 | 2.1 | 11.8 |

| 32 | IX800 | 816.4 | 841.32 | 843.7 | 844.58 | 840.42 | 846.66 | 851.16 | 829.4 | 1.54 | 5.16 | 14.2 | 17.6 | 43.03 | 2.2 | 13.3 |

| 34 | IX850 | 866.6 | 892.1 | 894.48 | 895.36 | 891.27 | 897.53 | 902.18 | 879.9 | 1.54 | 5.32 | 14.63 | 18.2 | 44.34 | 2.2 | 14.8 |

| 36 | IX900 | 918.7 | 945.78 | 948.27 | 949.19 | 945.13 | 951.41 | 956.19 | 932.6 | 1.61 | 5.48 | 15.06 | 18.8 | 45.65 | 2.3 | 17.1 |

| 38 | IX950 | 968.8 | 996.59 | 999.08 | 1000 | 995.96 | 1002.3 | 1 007.21 | 983.1 | 1.61 | 5.63 | 15.47 | 19.3 | 46.88 | 2.3 | 18.9 |

| 40 | IX1000 | 1021 | 1049.28 | 1051.88 | 1052.85 | 1048.83 | 1055.19 | 1 060.23 | 1035.7 | 1.68 | 5.77 | 15.88 | 19.9 | 48.12 | 2.4 | 20.9 |

| 42 | IX1050 | 1071.1 | 1100 | 1102.7 | 1103.71 | 1099.72 | 1106.1 | 1 111.26 | 1086.2 | 1.75 | 5.92 | 16.27 | 20.4 | 49.29 | 2.5 | 23 |

| 44 | IX1100 | 1121.3 | 1150.83 | 1153.53 | 1154.54 | 1150.62 | 1157 | 1 162.28 | 1136.8 | 1.75 | 6.05 | 16.64 | 21 | 50.43 | 2.5 | 25.1 |

| 46 | IX1150 | 1173.4 | 1203.55 | 1206.36 | 1207.4 | 1203.47 | 1209.91 | 1 215.31 | 1189.3 | 1.82 | 6.19 | 17.03 | 21.5 | 51.59 | 2.6 | 27.5 |

| 48 | IX1200 | 1223.6 | 1254.39 | 1257.2 | 1258.25 | 1254.38 | 1260.83 | 1 266.35 | 1239.8 | 1.82 | 6.32 | 17.39 | 22 | 52.68 | 2.6 | 29.9 |

Inspection and testing

No special requirements regarding hardness are required for the IX seal ring gasket as opposed to standard ring joint gaskets to ASME B16.20. There is no requirement for Charpy impact testing of seal ring materials.The IX seal grooves are identical for all pressure classes and dimensions are hence given per DN. The outer diameter DA3 of the grooves and the groove angle αA2 are only valid for the flat face flanges, i.e RI, PS, PB and OS flanges. For flanges with face bevel angle (WN, BL, IF and RT), these dimensions vary with the face angle.

Table 3.1 – Dimensions of IX seal ring gasket grooves

| DN | NPS | IX size |

DA1 mm |

DA3 mm |

E1 mm |

αA2 ° |

| 15 | ½ | IX15 | 20.8 | 30.83 | 5.30 | 15.0 |

| 20 | ¾ | IX20 | 25.8 | 35.82 | 5.30 | 15.0 |

| 25 | 1 | IX25 | 32.8 | 42.82 | 5.30 | 15.0 |

| 40 | 1½ | IX40 | 47.8 | 58.81 | 5.58 | 15.0 |

| 50 | 2 | IX50 | 59.8 | 71.80 | 6.19 | 15.0 |

| 65 | 2½ | IX65 | 72.8 | 85.79 | 6.79 | 15.0 |

| 80 | 3 | IX80 | 87.8 | 101.77 | 7.42 | 15.0 |

| 100 | 4 | IX100 | 113.8 | 129.75 | 8.40 | 15.0 |

| 125 | 5 | IX125 | 139.8 | 157.68 | 9.27 | 15.0 |

| 150 | 6 | IX150 | 167.7 | 187.66 | 10.12 | 15.0 |

| 200 | 8 | IX200 | 217.7 | 239.62 | 11.48 | 15.0 |

| 250 | 10 | IX250 | 271.7 | 299.58 | 12.90 | 15.0 |

| 300 | 12 | IX300 | 321.7 | 348.54 | 13.97 | 15.0 |

| 350 | 14 | IX350 | 353.7 | 381.51 | 14.63 | 15.0 |

| 400 | 16 | IX400 | 405.7 | 435.47 | 15.63 | 15.0 |

| 450 | 18 | IX450 | 455.7 | 487.43 | 16.54 | 15.0 |

| 500 | 20 | IX500 | 507.7 | 540.39 | 17.63 | 15.0 |

| 550 | 22 | IX550 | 557.7 | 592.35 | 18.45 | 15.0 |

| 600 | 24 | IX600 | 607.7 | 643.32 | 19.23 | 15.0 |

| 650 | 26 | IX650 | 659.5 | 696.23 | 20.00 | 15.0 |

| 700 | 28 | IX700 | 709.5 | 748.19 | 20.92 | 15.0 |

| 750 | 30 | IX750 | 761.5 | 801.15 | 21.65 | 15.0 |

| 800 | 32 | IX800 | 811.5 | 852.11 | 22.32 | 15.0 |

| 850 | 34 | IX850 | 861.5 | 903.07 | 22.97 | 15.0 |

| 900 | 36 | IX900 | 913.5 | 957.03 | 23.82 | 15.0 |

| 950 | 38 | IX950 | 963.5 | 1007.99 | 24.44 | 15.0 |

| 1000 | 40 | IX1000 | 1015.5 | 1060.95 | 25.06 | 15.0 |

| 1050 | 42 | IX1050 | 1065.5 | 1111.91 | 25.65 | 15.0 |

| 1100 | 44 | IX1100 | 1115.5 | 1162.87 | 26.42 | 15.0 |

| 1150 | 46 | IX1150 | 1167.5 | 1215.83 | 27.00 | 15.0 |

| 1200 | 48 | IX1200 | 1217.5 | 1266.79 | 27.54 | 15.0 |

Table 3.2 – IX seal ring dimensional tolerances

| Dimension | Size range |

Tolerance mm |

| ID (DG1) |

≤ IX80 > IX80 ≤ IX350 > IX350 |

±0.2 ±0.3 ±0.4 |

|

Diameter bottom recess (DG5) |

≤ IX80 > IX80 ≤ IX350 > IX350 |

±0.1 ±0.2 ±0.4 |

| Diameter, DG6 |

≤ IX150 > IX150 |

-0/+0.1 -0/+0.2 |

| OD of ring (DG7) |

≤ IX150 > IX150 |

-0/+0.1 -0/+0.2 |

| Height, HG2 |

≤ IX40 > IX40 ≤ IX200 > IX200 ≤ IX400 > IX400 ≤ IX600 > IX600 ≤ IX800 > IX800 ≤ IX1000 > IX1000 |

±0.05 ±0.1 ±0.2 ±0.3 ±0.4 ±0.5 ±0.6 |

| Height to end angle (HG3) |

≤ IX40 > IX40 ≤ IX200 > IX200 ≤ IX400 > IX400 ≤ IX600 > IX600 ≤ IX800 > IX800 ≤ IX1000 > IX1000 |

±0.05 ±0.1 ±0.2 ±0.3 ±0.4 ±0.5 ±0.6 |

| Height of ring (HG5) |

≤ IX150 > IX150 ≤ IX350 > IX350 ≤ IX550 > IX550 ≤ IX700 > IX700 ≤ IX900 > IX900 ≤ IX1100 > IX1100 |

±0.05 ±0.1 ±0.15 ±0.2 ±0.25 ±0.3 ±0.35 |

Copyright protection: This article was originally created by Jayuseal. Citing this article, please indicate the source: /r3/ix-seal-ring-gasket.html

- End

- Next: IX Seal Rings